Insulating Oil 101: Uses, Types & Best Options for Canadian Applications

By Jason Sherlock

Director of Operations

Aevitas Insulating Oil Division – Brantford, Ontario

CONTENTS

What is insulating oil and where is it used?

Why is insulating oil used in electrical equipment?

How does insulating oil cool an electrical transformer?

What types of insulating oils are available in the Canadian market?

What is the difference between naphthenic and paraffinic oils?

What else should be considered when choosing an insulating oil?

What is the difference between Type I (uninhibited) and Type II (inhibited) insulating oil

When should Type I versus Type II be used?

What is the difference between Class A and Class B insulating oil?

When should Class A versus Class B be used?

What type of insulating oil does Aevitas sell and why is it one of the best options for use in Canada?

FAQs about CALTRAN C50

Does CALTRAN C50 contain inhibitors?

How well do CALTRAN C50 products perform in cold climates?

How does CALTRAN C50 help extend the life of the oil and equipment?

Where are CALTRAN C50 products available?

What sizes are CALTRAN C50 products available in?

Why is CALTRAN C50 the best insulating oil for use in Canada?

How can I order CALTRAN C50 products and how long does it take?

Does Aevitas provide new oil filling services?

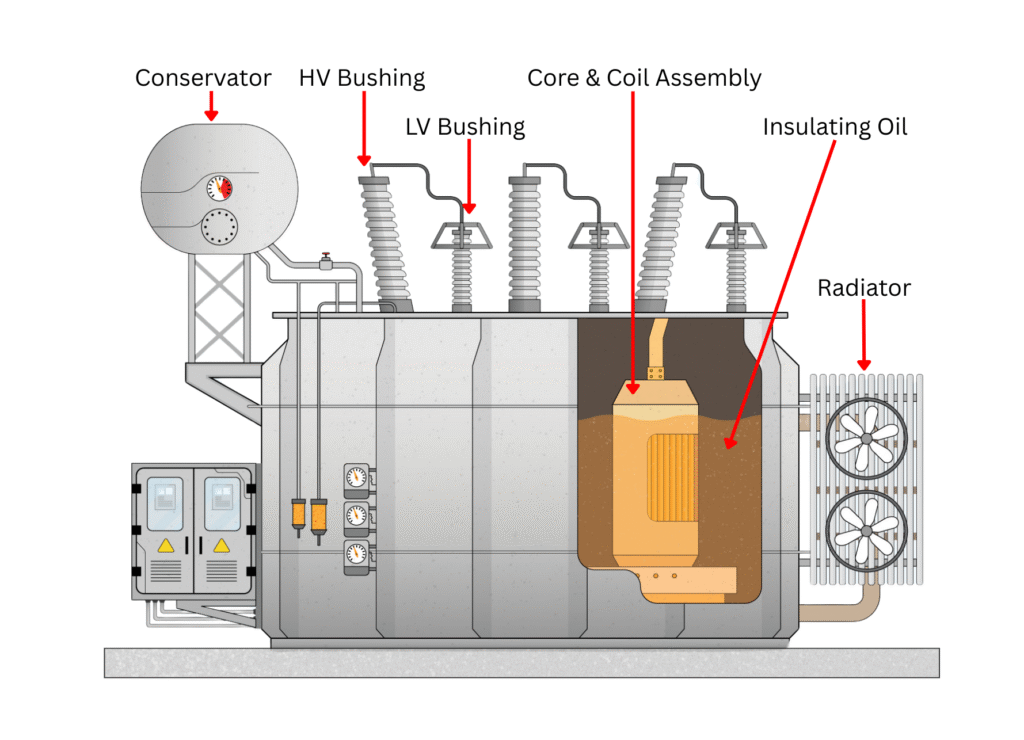

Insulating oil, also known as transformer oil, is a specialized mineral-based fluid with excellent electrical insulating properties and stability at high temperatures. Insulating oil is used in electrical equipment, including:

- power transformers,

- oil-filled circuit breakers (OCBs),

- bushings,

- switches, and

- capacitors.

Why is insulating oil used in electrical equipment?

Insulating oil’s high dielectric strength and thermal conductivity make it essential for the safe and efficient operation of any type of oil-filled electrical equipment.

In particular, insulating oil serves three primary functions in electrical equipment:

- Insulation—Prevents electrical discharge between live parts and grounded components.

- Cooling—Dissipates heat generated during operation.

- Arc Suppression—Minimizes electrical arcing within equipment.

Another important property of insulating oil is its ability to prevent oxidation of the cellulose paper insulation. The transformer oil acts as a barrier between atmospheric oxygen and the cellulose; by preventing direct contact with the air, oxidation is minimized.

In addition, insulating oil helps to preserve the transformer’s core and windings (or core and coil assembly), as these are fully immersed inside the oil.

As shown in this image, the transformer’s core and coil assembly are fully immersed in the insulating oil.

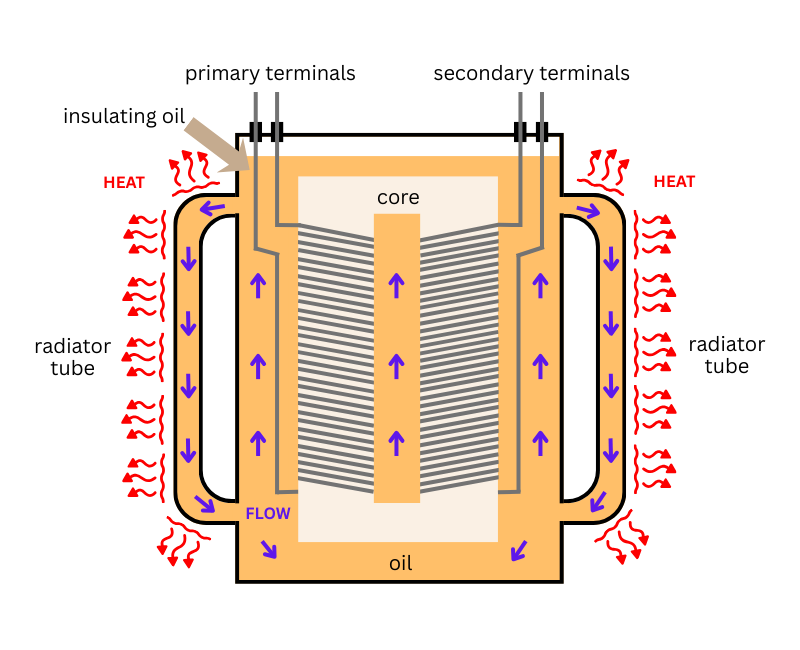

How does insulating oil cool an electrical transformer?

Insulating oil cools a transformer by absorbing heat from the core and windings and then dissipating it through natural convection. As the oil around the active components heats up, it becomes less dense and rises, moving towards the transformer’s exterior. In larger transformers, this heated oil then flows through external radiators, where it releases heat to the surrounding air. As the oil cools, it becomes denser and sinks back down toward the tank floor, repeating the cycle.

What types of insulating oils are available in the Canadian market?

There are two main types of mineral-based insulating oils used in transformers operating in Canada:

- Naphthenic-based insulating oil (naphthenic oil), e.g., CALTRAN™ C50, Voltesso

- Paraffinic-based insulating oil (paraffinic oil), e.g., Luminol

In some cases, other non-oil types of insulating fluid are used, including: natural and synthetic ester fluids; silicone fluids; beta fluids; and nanofluids. These fluids are significantly more expensive than mineral-based lubricating oils, but they are recommended when operating high-voltage electrical equipment in an enclosed environment where fire potential is a concern. (Note: This article focuses on just mineral-based oils, not these other fluids.)

What is the difference between naphthenic and paraffinic oils?

Naphthenic oil can oxidize more quickly than paraffinic oil. However, the sludge produced during oxidization of naphthenic oil is more soluble and does not settle at the transformer’s bottom, ensuring unobstructed oil circulation and an effective transformer cooling system.

In comparison, paraffinic oil oxidizes more slowly than naphthenic oil, but its sludge is insoluble and collects at the tank’s bottom, hindering the transformer’s cooling system. Another problem with paraffinic oil is that the dissolved waxes inside of it can lead to a high pour point. Although this is not an issue in warmer climate conditions, it can be an issue in the Canadian climate. Despite these disadvantages, paraffinic oil is still commonly used in Canada because of widespread recognition of common brands available.

Naphthenic oil is the superior choice for most locations in Canada.

What else should be considered when choosing an insulating oil?

In addition to differences in the base composition of lubricating oils (i.e., naphthenic or paraffinic), there are two other key variables to consider when choosing a lubricating oil: Type I or Type II; and Class A or Class B.

- What is the difference between Type I (uninhibited) and Type II (inhibited) insulating oil? While both Type I and Type II oils have similar basic physical and electrical properties (such as dielectric strength, water content, and interfacial tension), Type II oils contain additives (i.e., inhibitors) that improve oxidation resistance and provide long service performance with reduced sludge formation under high temperatures and for extended service life. Specifically, they include 0.08 to 0.4% by weight of antioxidant additives like DBPC or BHT.

- When should Type I versus Type II be used? The presence of inhibitors in Type II oils helps them perform better in highly thermal and oxidative-stressed applications, making them ideal for use in critical infrastructure, such as power transmission networks, industrial transformers, and high-capacity substations. Normally, Type I oils are selected for systems with operational conditions that are less harsh or have specific environmental considerations.

- What is the difference between Class A and Class B insulating oil? Class A and Class B refer to different thermal classes for insulating oil, with Class A being suited for colder temperatures than Class B.

- When should Class A versus Class B be used? According to the National Standard of Canada CAN/CSA-C50-14, Class A oil is “recommended for use in power transformers, especially those subject to cold start-up or that have forced oil cooling, including associated load tap changers, all of which operate in ambient temperatures below ‑25 °C.” Class B oil is “suitable for use in electrical equipment (except for minimum oil circuit breakers and high-voltage cables) that operates in ambient temperatures of ‑25 °C and above”. Note: Such oils have been found to be suitable for use in most distribution transformers at ambient temperatures below ‑25 °C”.

What type of insulating oil does Aevitas sell and why is it one of the best options for use in Canada?

Aevitas Inc. is the exclusive distributor of CALTRAN C50 products, which are manufactured by Calumet Specialty Products Partners, L.P. Aevitas chose to partner with Calumet because they are a leading insulating oil manufacturer, have a state-of-the-art refinery, and use premium naphthenic stock to manufacture CALTRAN C50 products specifically formulated for use in Canada.

FAQs about CALTRAN C50

- Does CALTRAN C50 contain inhibitors? Yes, CALTRAN C50 insulating oils are available in Type II (inhibited) in both Class A and Class B. The oxidation inhibitor content for Class A is 0.27% and Class B is 0.26%. If the application does not require inhibited oils, CALTRAN C50 is also available in Type I (uninhibited) in both Class A and Class B.

- How well do CALTRAN C50 products perform in cold climates? All CALTRAN C50 products perform extremely well in cold climates, but the exact product you choose will vary based on the use case and conditions. CALTRAN C50A products are fluid 20°C beyond the CSA-C50-Class A specification of ‑46°C, and CALTRAN C50B products are fluid 15-25°C beyond the Class B specification of ‑40°C. The robust cold temperature performance extends beyond pour point and is further validated by the low temperature fluidity (or low viscosity). The viscosities at ‑40°C of CALTRAN C50A products are nearly 30% lower than the C50 Class A specification of ≤2,500 mm2/s (cSt), and the viscosities at ‑40°C of CALTRAN C50B products are 67% lower than the C50 Class B specification of ≤6,000 mm2/s (cSt). Low viscosity at cold temperatures ensures reliable startup of transformers and proper operation of circuit breakers.

- How does CALTRAN C50 help extend the life of the oil and equipment? Contaminants and compounds in insulating oil—such as acids and sludge from oxidation—decrease service life and increase the risks for unplanned downtime. These byproducts affect metal corrosion of electrical components, and they also influence dielectric breakdown strength and heat transfer of insulating oil. CALTRAN C50 products have exceptional oxidation stability and promote outstanding resistance to oxidation and sludge formation, which help support long service life of the oil and equipment.

- Where are CALTRAN C50 products available? CALTRAN C50 products are readily available for immediate delivery across Canada, from either the Aevitas Insulating Oil Division located in Brantford, Ontario, or from Aevitas locations in Edmonton, Alberta and Maple Ridge, British Columbia.

- What sizes are CALTRAN C50 products available in? CALTRAN C50 products are available in a wide range of sizes for various needs: 20 litre pails for equipment top-ups; 205 litre drums; and 1,000 litre IBC totes for larger projects. For even larger volumes, Aevitas delivers by tanker truck or rail car to original equipment manufacturers (OEM) and organizations such as power generators and utilities with large storage tanks.

- Why is CALTRAN C50 the best insulating oil for use in Canada? CALTRAN C50 is a line of Arctic-grade insulating oils that features exceptional low-temperature fluidity, oxidation stability and corrosion control, making them an ideal solution for the Canadian climate. CALTRAN C50 also improves circulation and heat transfer. The product has high dielectric strength, and it assists in the prevention of corona discharge and arcing. The high level of refining removes corrosive sulfur compounds, resulting in corrosion control. All CALTRAN C50 insulating oils meet or exceed Canadian Standards Association (CSA) C50-14 specifications.

- How can I order CALTRAN C50 products and how long does it take? Requesting a quote and placing an order is simple—reach out to Aevitas at our Insulating Oil Division in Brantford by calling toll-free 877-448-5900 or emailing insulatingoil@aevitas.ca.

Does Aevitas provide new oil filling services?

Yes, Aevitas has a highly trained and experienced team with dedicated service equipment (mobile oil processing units and dedicated insulating oil tankers) to provide many on-site services including degasification/oil circulation of existing transformers, vacuum filling of new transformers, and retrofilling (oil replacement) of existing transformers, which is a proven method to reduce PCB contamination levels.

Since the inception of the partnership with Calumet (the producer of CALTRAN C50) in 2021, Aevitas has distributed more than 23 million litres of CALTRAN C50 Insulating Oils throughout Canada.

Aevitas also offers oil draining of end-of-service, or spent, insulating oil from equipment.

For more information about CALTRAN C50, visit Caltran C50 Transformer Oils | Premium Naphthenic Insulating Oils.

ABOUT THE AUTHOR

Jason Sherlock has been the Director of Operations for the Aevitas Insulating Oil Division for over 20 years and possesses an extensive knowledge of the high-voltage electrical service industry with over 30 years related experience, including tenures at Westinghouse, ABB, and Siemens Canada. Jason currently sits on the Canadian Standards Association (CSA) Technical Committee on Transformer and Switch Oils. He lives in Caledonia, Ontario, Canada with his wife and three sons.